Firstly we need to understand how does Evercrete DPS work?

When cement sets it forms a chemical reaction with water to provide calcium silicate hydrate which is the chemical producing the strength of cement and concrete. During the hydration process water that is not chemically combined with the calcium silicate dries out within the concrete matrix leaving voids through which water can re-enter and disrupt the concrete or assist in the corrosion of embedded reinforcement. Evercrete DPS penetrates the pore structure of hydrated cement and reacts with the alkalis of sodium and potassium present in the concrete to produce a sodium silicate hydrate, which has both secondary cementing and waterproofing properties. Evercrete In addition it forms a chemical reaction which makes it part of the concrete so once applied it remains for the life of the concrete and cannot be removed unlike silanes and siloxanes which are essentially pore blockers.

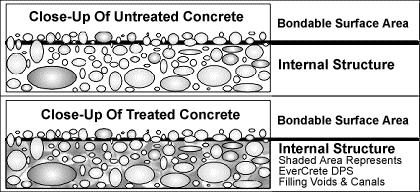

It is however important to note that the reactions take place beneath the surface of the concrete, hence the reasons why Evercrete DPS is not visible once it has been applied to the concrete and secondly why it will not affect the bonding between the paint and the concrete.

We wish to illustrate the following:-

The above sketch shows that the Evercrete reaction takes place below the surface.

The molecular structure of concrete is big enough to allow Evercrete DPS to penetrate by capillary suction. This penetration can be up to 2-3cm (depends on the density of the concrete).

In conclusion:

- Since Evercrete DPS forms part of the concrete matrix as explained above it inherits the same characteristics as the concrete and thus will not increase or degrease the concrete’s ability to withstand cold temperatures. The same goes for high temperatures.

- Since Evercrete DPS is a reaction that is taking place below the surface, (see sketch above), and if there is an oil spill, a stain will show up. But what it means is that the oil is only laying on the top surface of the concrete and has not penetrated the actual concrete structure. Evercrete DPS treated concrete will prevent the penetration of oil into the concrete.

- Evercrete DPS treated concrete will allow the concrete to breath, so if the type of gasses are of the same molecular structure than oxygen then it will travel through the concrete but if the gasses have a bigger molecular structure the DPS will block the gasses. In this instance the type of concrete used is also a factor in preventing gasses from travelling through the concrete.